Reinventing how natural gas is converted into usable energy

Delivering low-emission industrial heat without fuel switching, major infrastructure changes, or operational disruption.

For many facilities, emissions reduction is no longer optional, yet the available pathways remain expensive, complex, or operationally disruptive.

Industrial heat underpins oil & gas and other energy-intensive industries, but traditional combustion-based systems are among the largest sources of emissions. As carbon pricing, regulatory pressure, and emissions reporting requirements increase, these systems are becoming not just an environmental liability, but a growing economic one.

Today’s decarbonization options often force operators into difficult tradeoffs. Carbon capture adds significant capital and operating cost, while electrification and hydrogen introduce infrastructure dependence, reliability risk, and uncertain economics. In many cases, the cost of compliance outweighs the value created.

Operators need solutions that reduce emissions without increasing operating risk or cost and that work within existing systems, not against them.

Industrial heat is essential and increasingly costly to decarbonize

A practical new approach to industrial heat

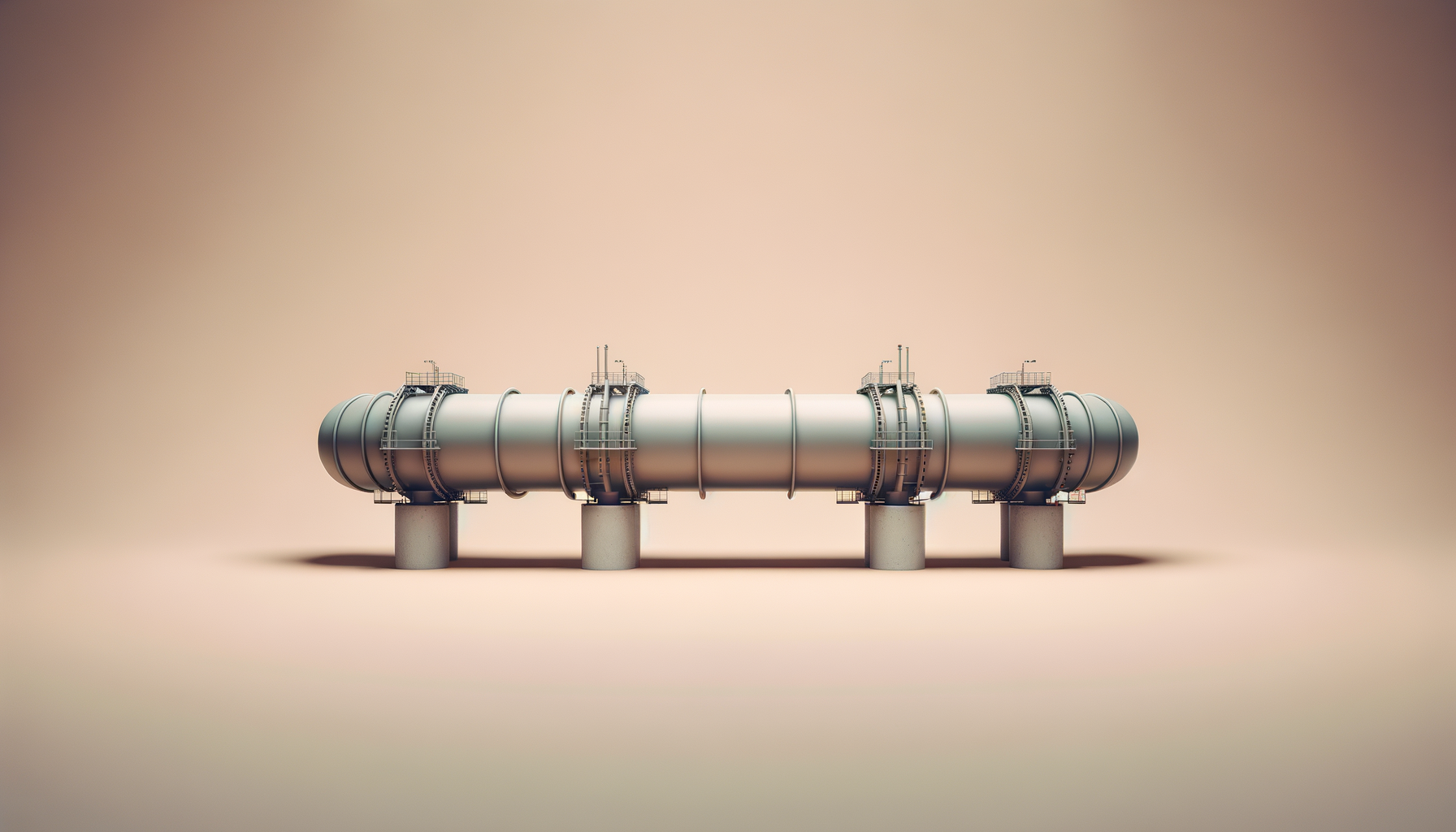

DOBox replaces natural gas combustion with a drop-in catalytic process that delivers the same high-grade industrial heat operators rely on while avoiding CO₂ emissions. By controlling how energy and carbon are released, DOBox diverts carbon into valuable chemical products, turning emissions reduction into an economically compelling outcome.

The result is a low-emission heat solution designed to integrate with existing systems, without fuel switching, grid dependence, or operational disruption.

Designed for real-world industrial operations

Decarbonizing industrial heat requires more than new fuels or theoretical infrastructure. It requires solutions that respect reliability, safety, and cost constraints.

DOBox is designed to integrate with the systems operators rely on today, delivering emissions reductions without increasing operational risk or complexity.

✅ Drop-in compatibility with existing natural gas systems

✅ No fuel switching or grid dependence

✅ Designed for continuous, high-temperature operation

✅ Aligned with economic and regulatory realities

Where DOBox Fits

DOBox is built for applications where reliable, high-grade heat is essential and emissions reductions must align with operational and economic constraints.

Oil & gas production and processing

Refineries and fired heaters

Boilers and industrial steam generation

Energy-intensive industrial facilities